Tube blown glassware manufacturing (manual blowing)

As SHULOPAL’s borosilicate glass factory also producing high borosilicate glass tubes, so from 2019, we started manufacturing tube blown glassware items.

Introduction

The tube glass processes typically involves two methods: manual blowing and mechanized production. SHULOPAL produces 105,000 machine-made products and 15,000 hand-blown products daily.

Porduciton lines

0

Daily production by pieces

109000

Number of workers

89

How to make Tube Blown Dinnerware Step by Step

Step#1 Glass tubes

Glass tubes manufactured from own borosilciate glass factory, therefore, our tube blown glass products have significant cost advantages.

1

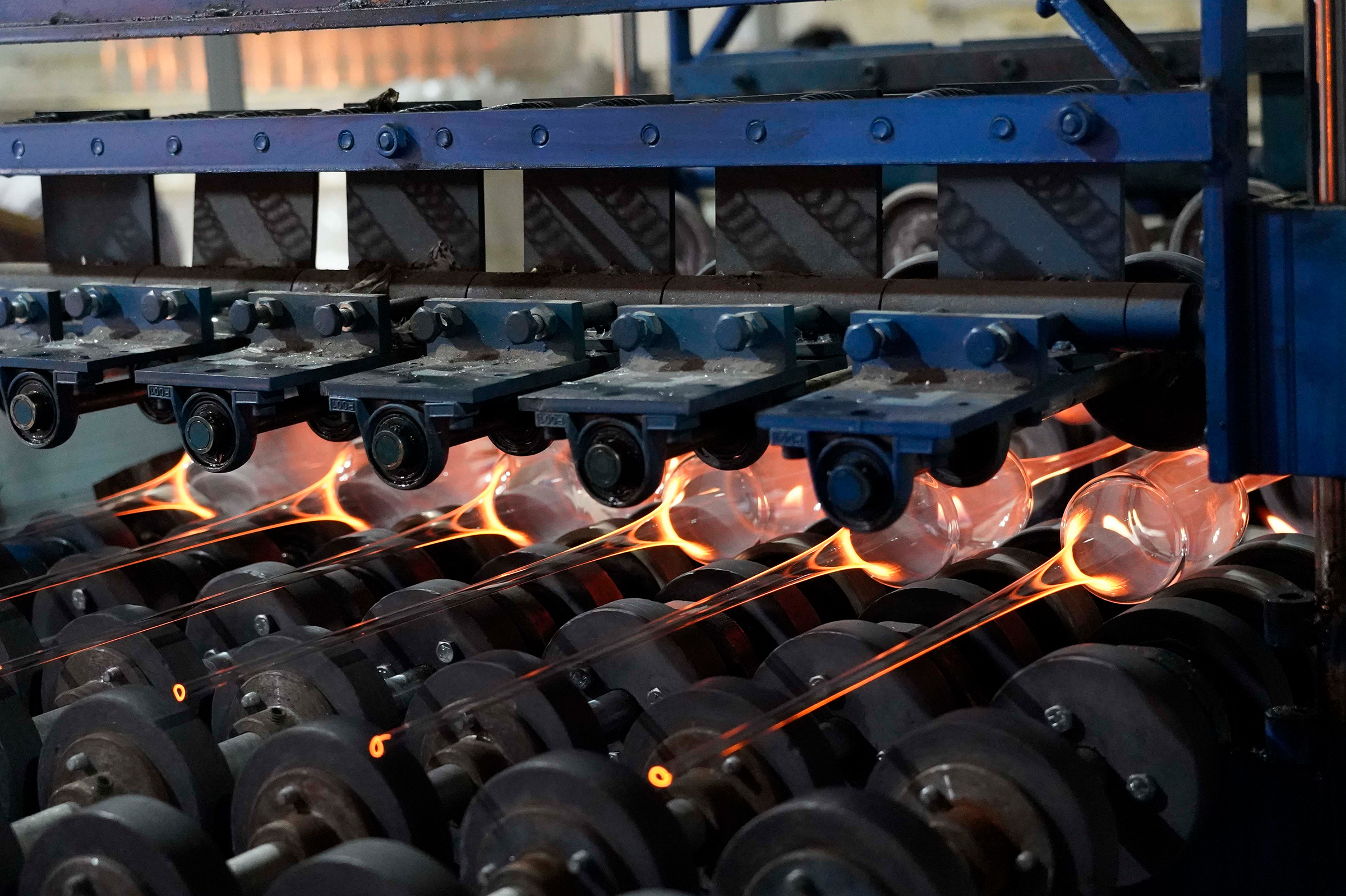

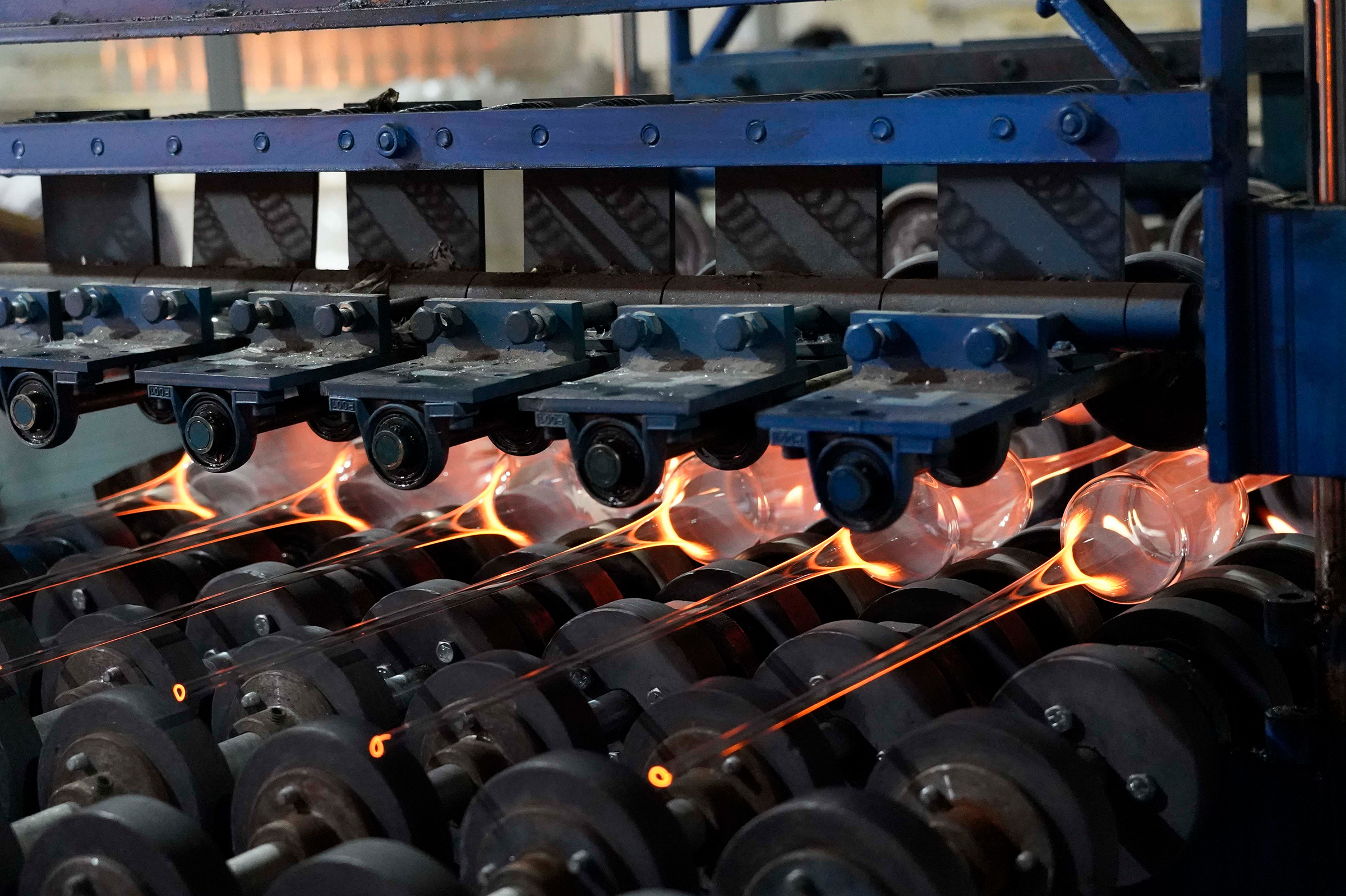

Step#2 Tube drawing

According to the size of the product to be manufactured, the glass tube is drawn and cut to a specified length using a tube drawing machine.

2

Step#3 Glass blowing

Experienced glassblowing masters heat the trimmed tubing units and place them into molds, then blow them into the desired shape and size. Open molds are generally used, but hinged molds are employed if the product surface has textures or irregular shapes.

3

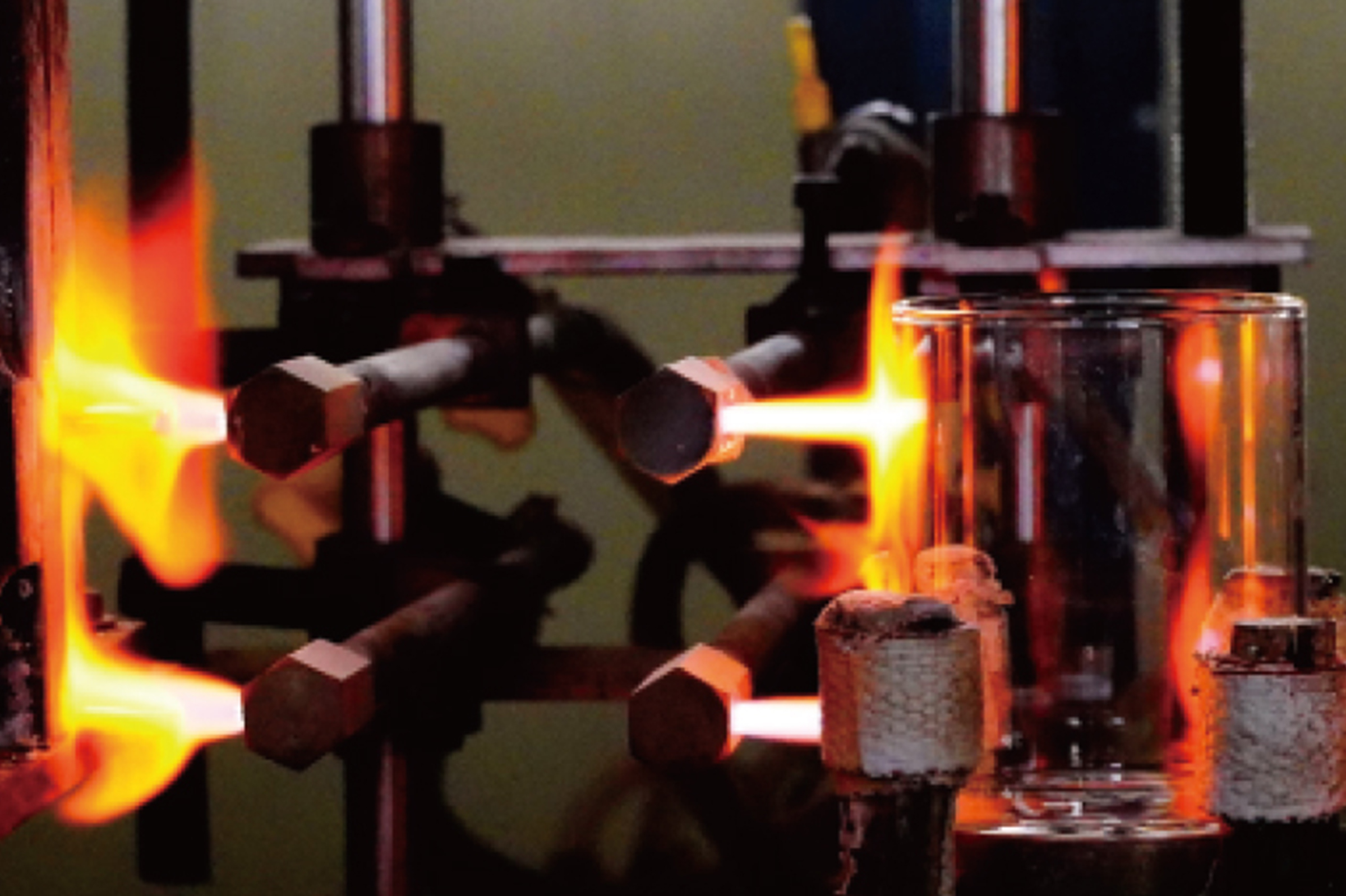

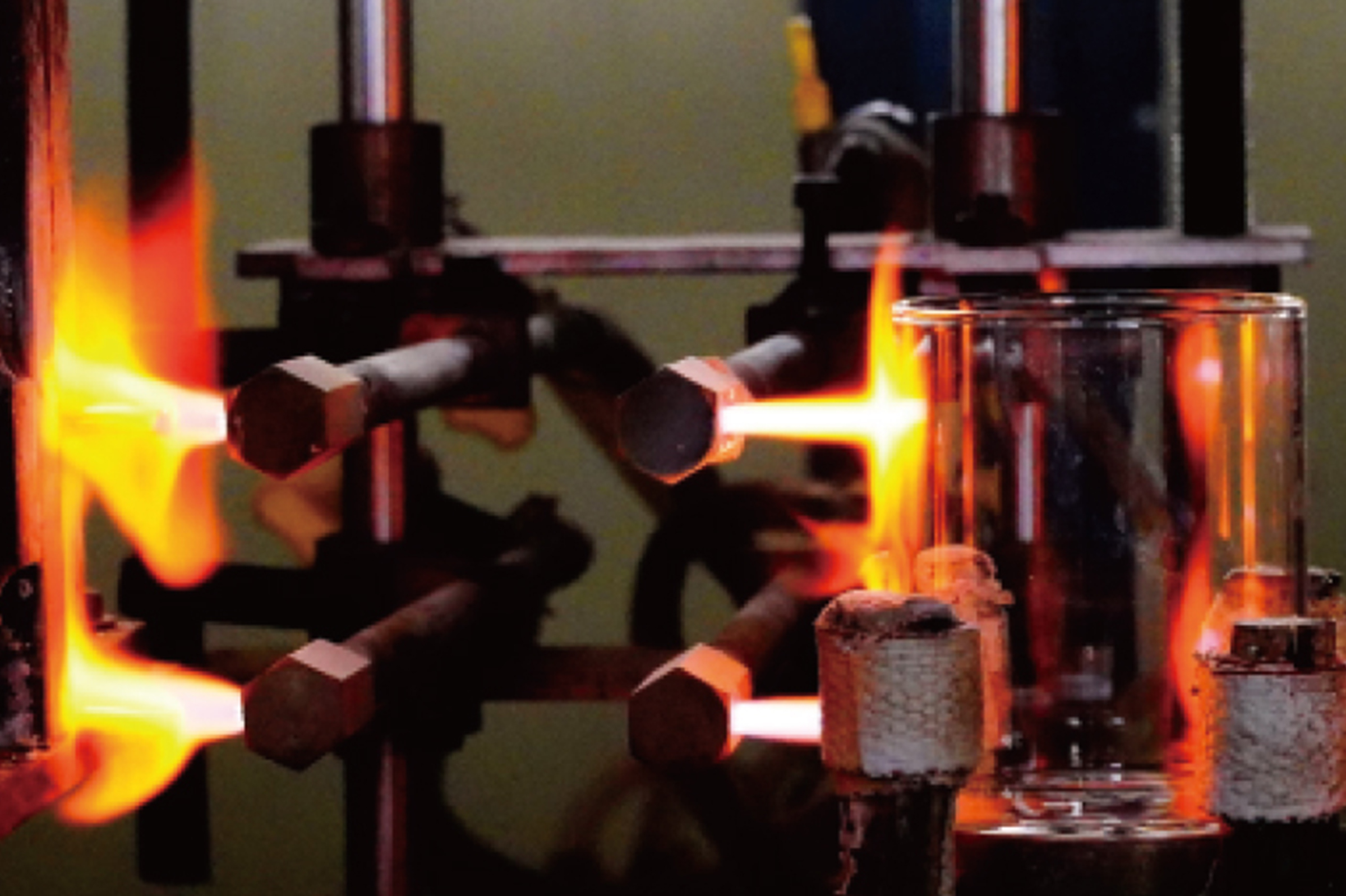

Step#4e Mouth cutting

The tube is drawn and cut along a high-temperature flame line to form the rim of a single-layer cup or pot.

4.1

Step#4f Liner punching

Excess tubing is drawn and cut off using a high-temperature flame line, which also increases the thickness of the softened glass layer at the cut position, suitable for inward pressing of the liner punch to form a double-layer cup liner. Skilled SHULOPAL workers ensure the liner thickness is no less than 0.7mm, with height variations within 2mm for products from the same batch.

4.2

Step#5g Make pour

A single-wall teapot or cup can also have a compressed or pulled spout, or feature a long spout extending from the body

5.1

Step#5h Bottom close

Use a high-temperature flame wire to draw and cut off the excess tubing at the bottom. After perforating the bottom, place it on a graphite plate at a set temperature and let it rest until the bottom becomes flat.

5.2

Step#6 Stick handle

Heat both the glass handle and the joint on the cup body, then attach the handle.

6

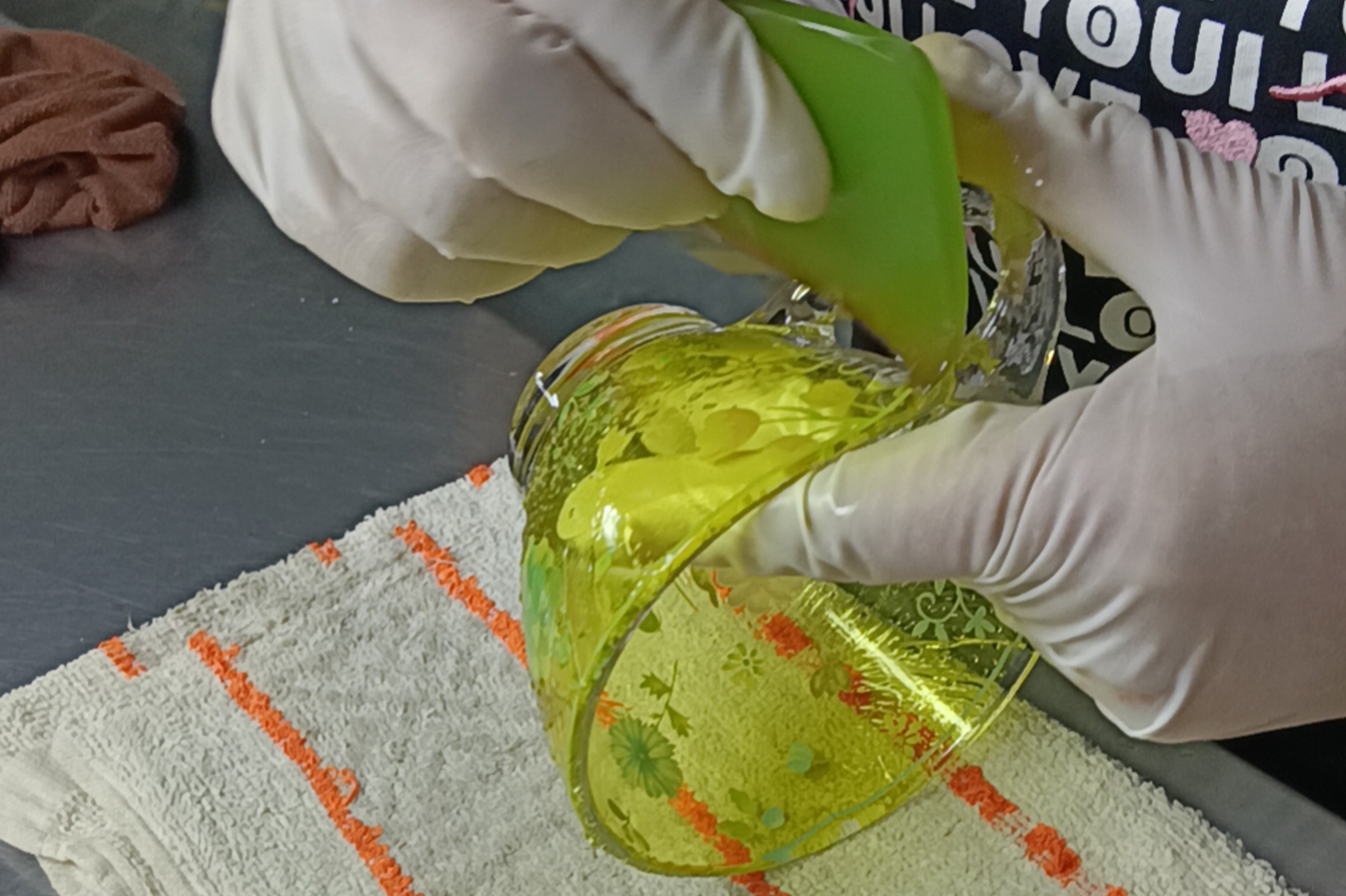

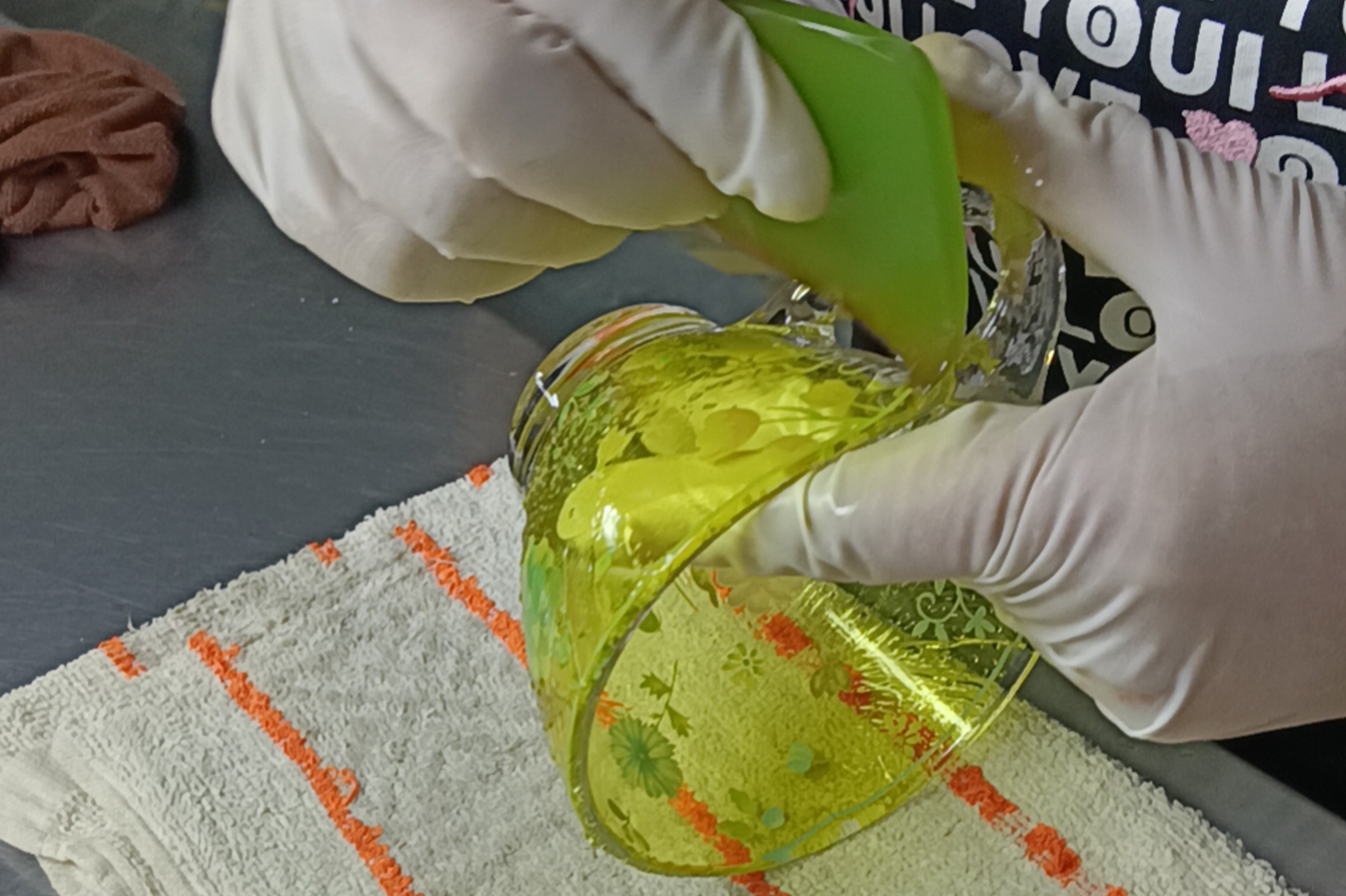

Step#7 Fill decoration

You can also fill the double-walled cup with your favorite dried flowers, shells, and other decorations, making it very beautiful!

7

Step#8 Bottom Sealing

After annealing and cooling, the bottom vents of the double-walled cup need to be sealed.

8

Step#8 Bottom Sealing

After annealing and cooling, the bottom vents of the double-walled cup need to be sealed.

9

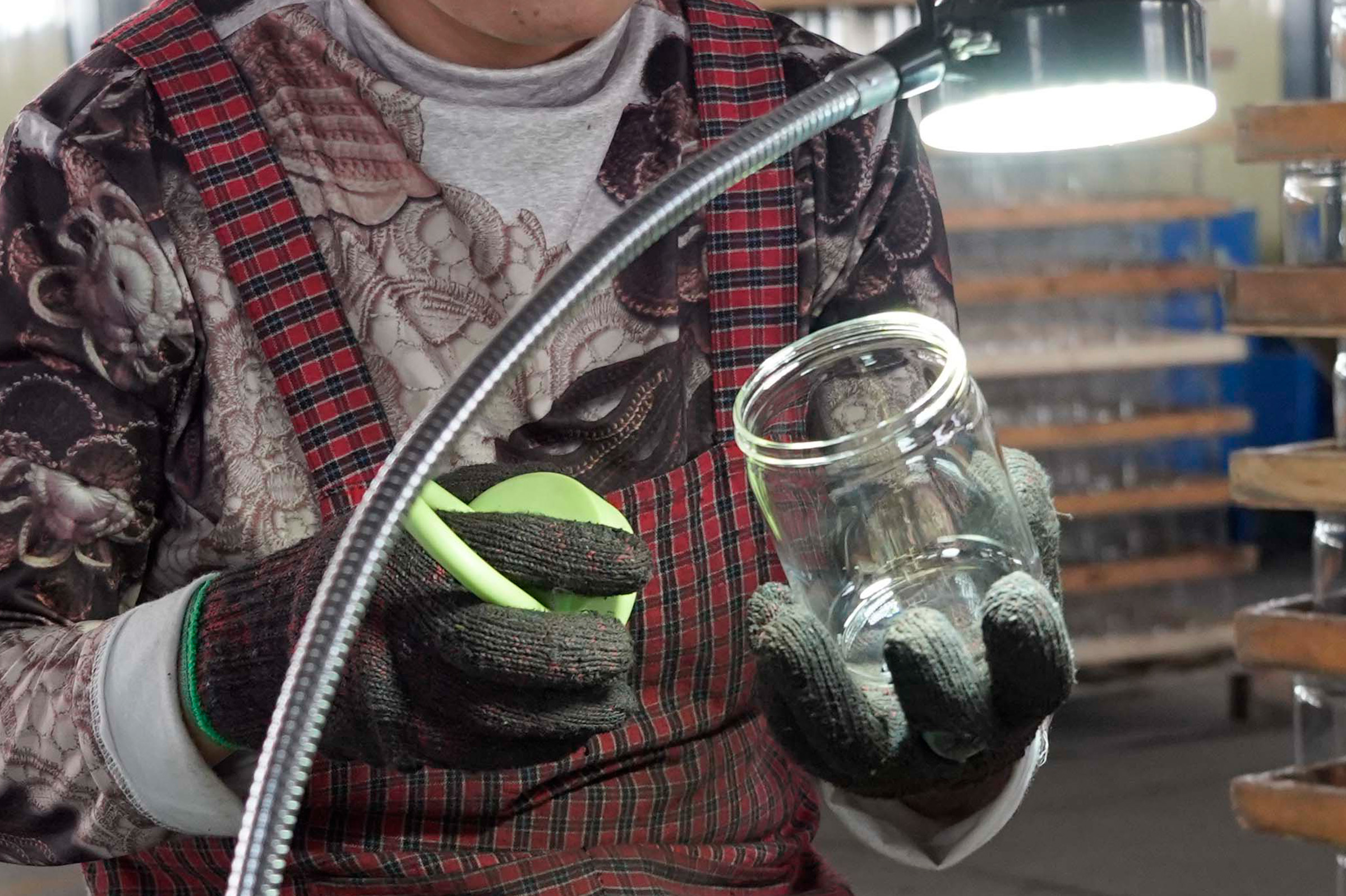

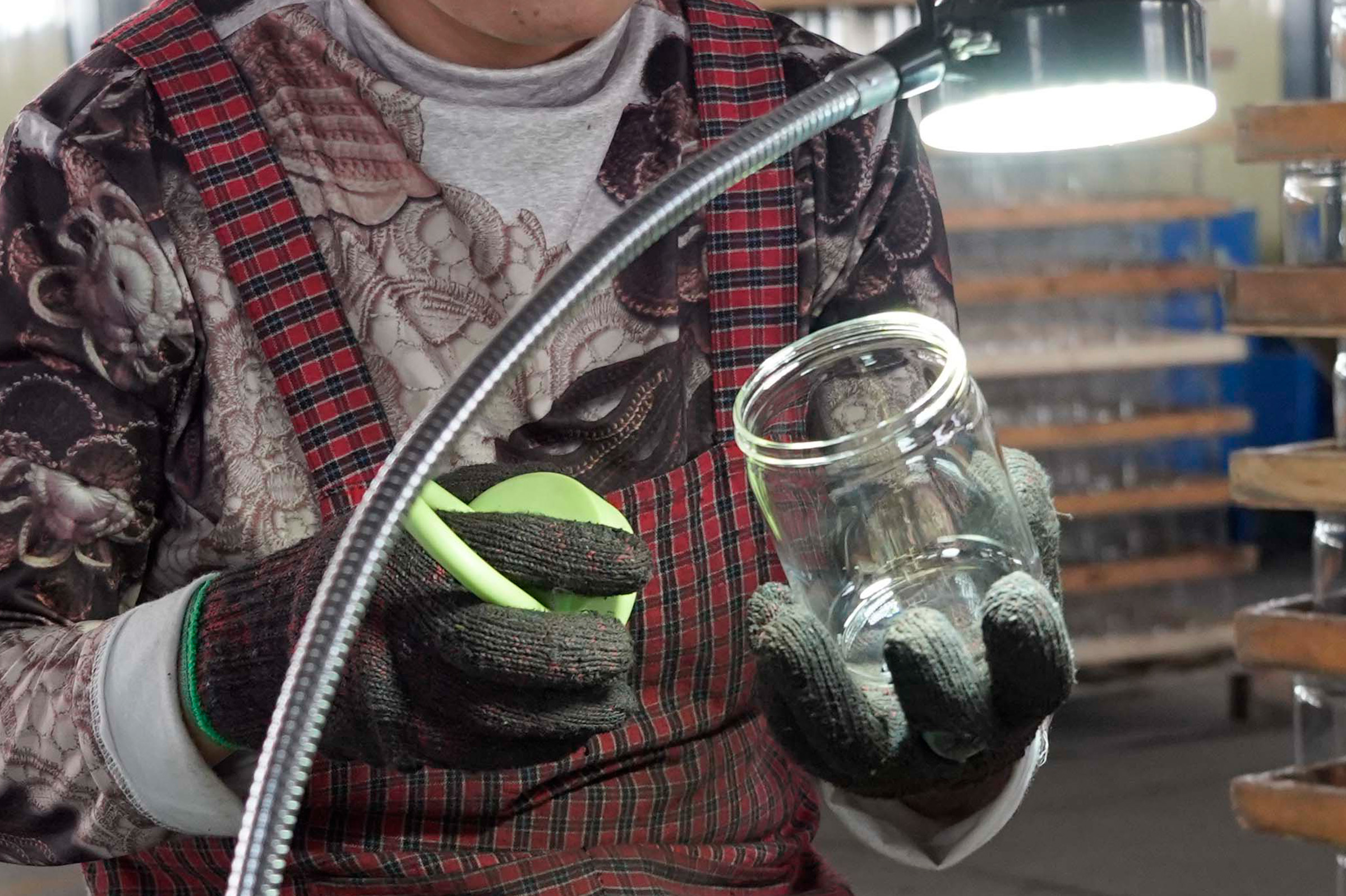

Step#9 Finished product QC

The quality inspection team will conduct quality checks on finished products according to inspection standards.

10

Step#10 Packaging

Skilled packers securely package products according to customer specifications.

11

Step#10 Packaging

Skilled packers securely package products according to customer specifications.

12