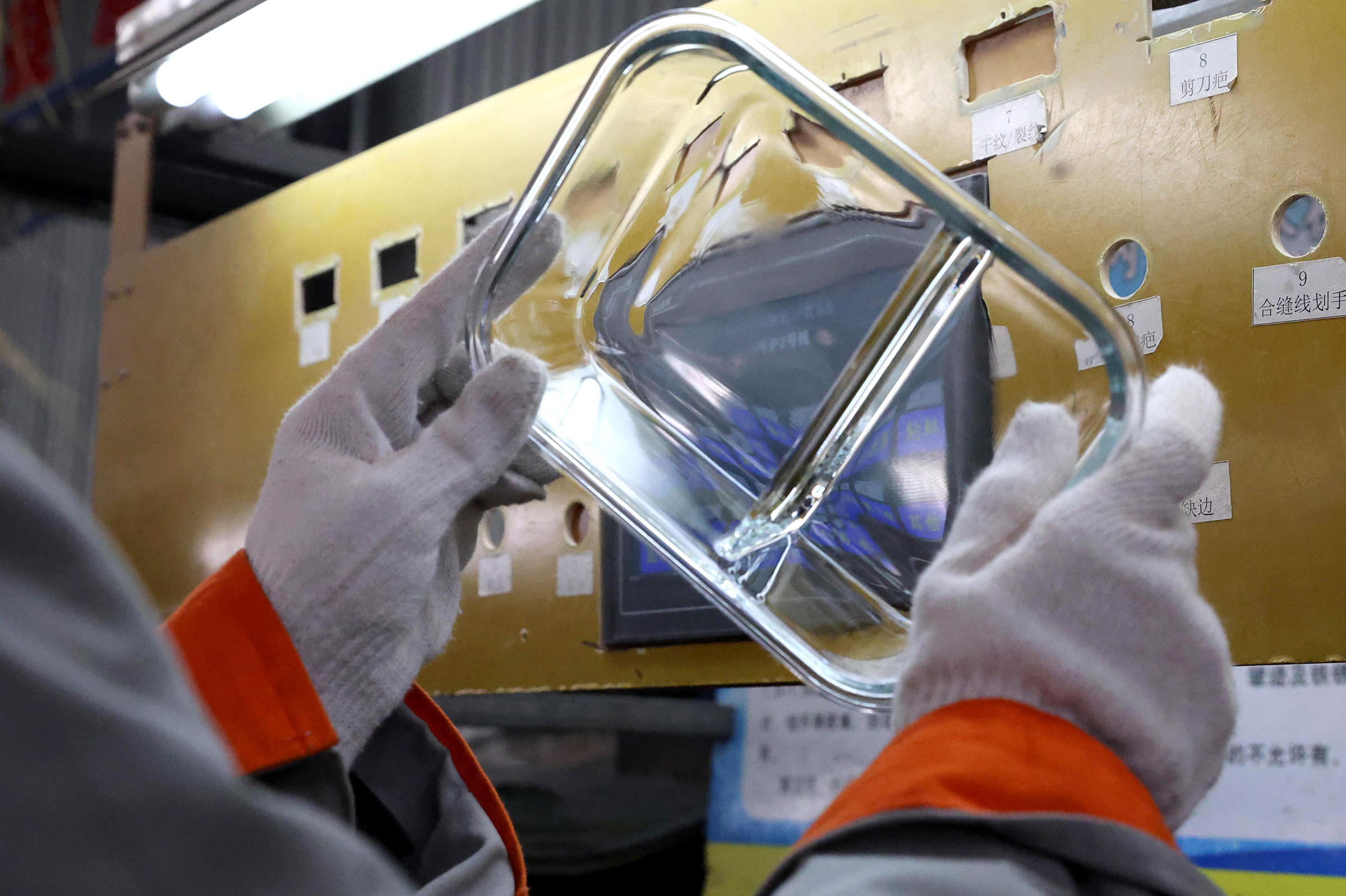

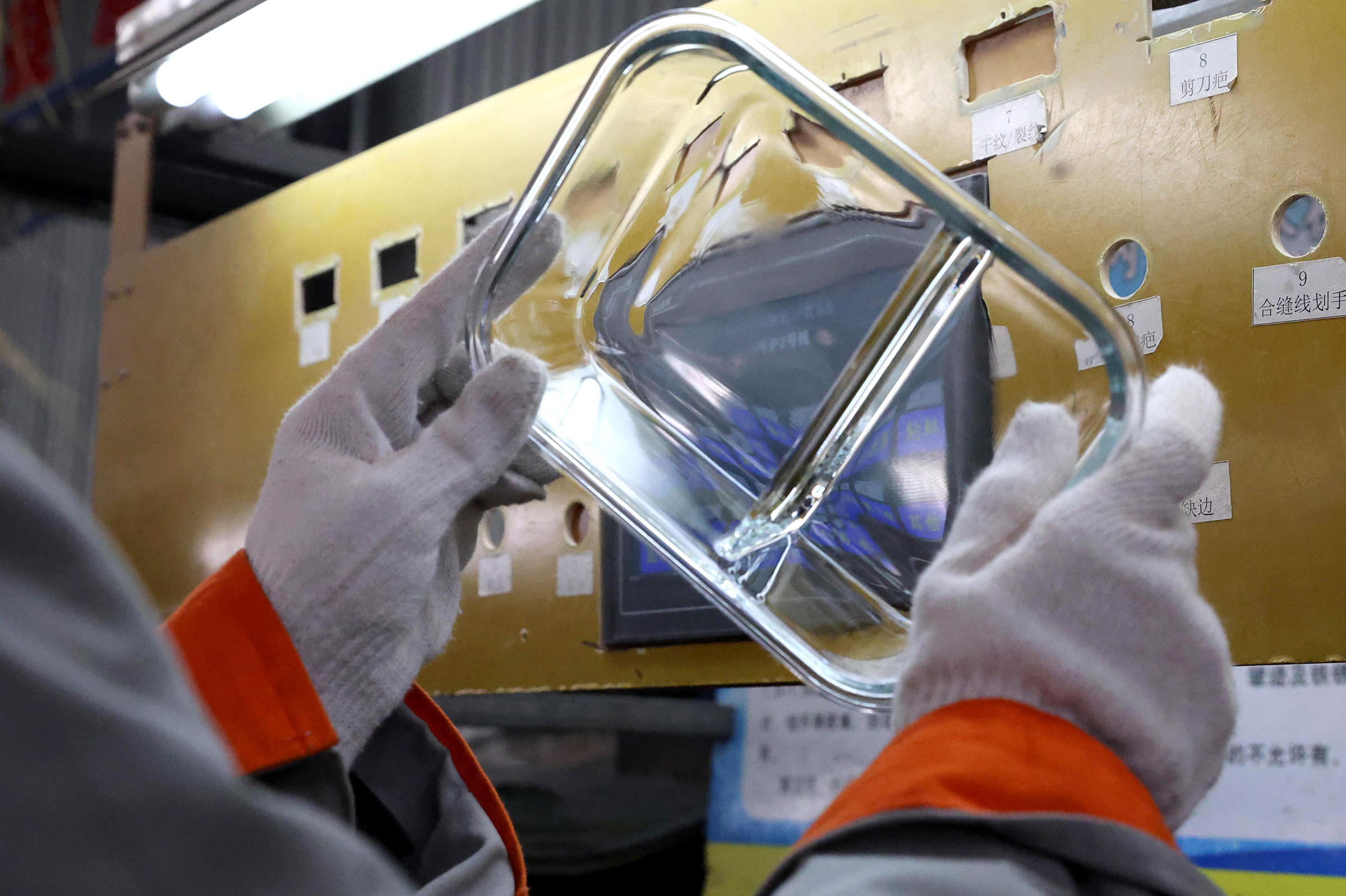

In 2018, SHULOPAL embarked on its journey in the borosilicate glassware industry. Today, our borosilicate glass plant boasts a daily production capacity of 180,000 pressed items, Including all kinds of glass food containers, glass serving bowls, glass oven dishes, glass casseroles, and other kitchen accessories..

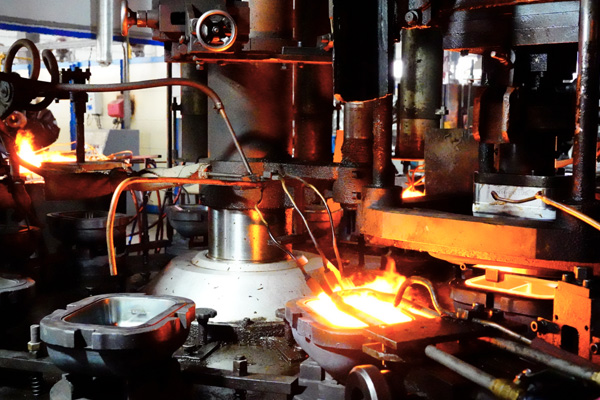

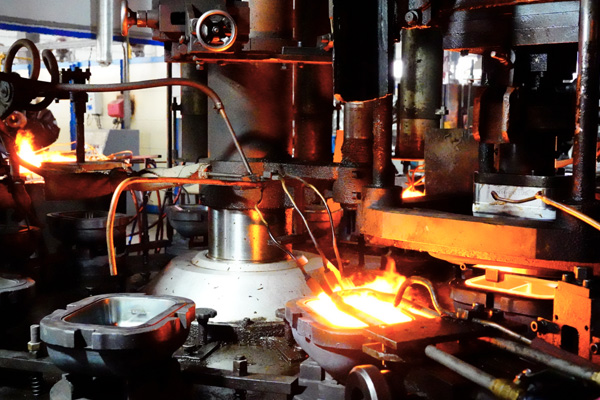

The borosilicate glass food containers,bakeware, mixing bowls are made by press process. A molten glass gob falls onto the bottom mold of the press, and the punch above presses the glass block into the desired shape. There’re 12 manufacturing process lines at SHULOPAL borosilicate glassware production base.