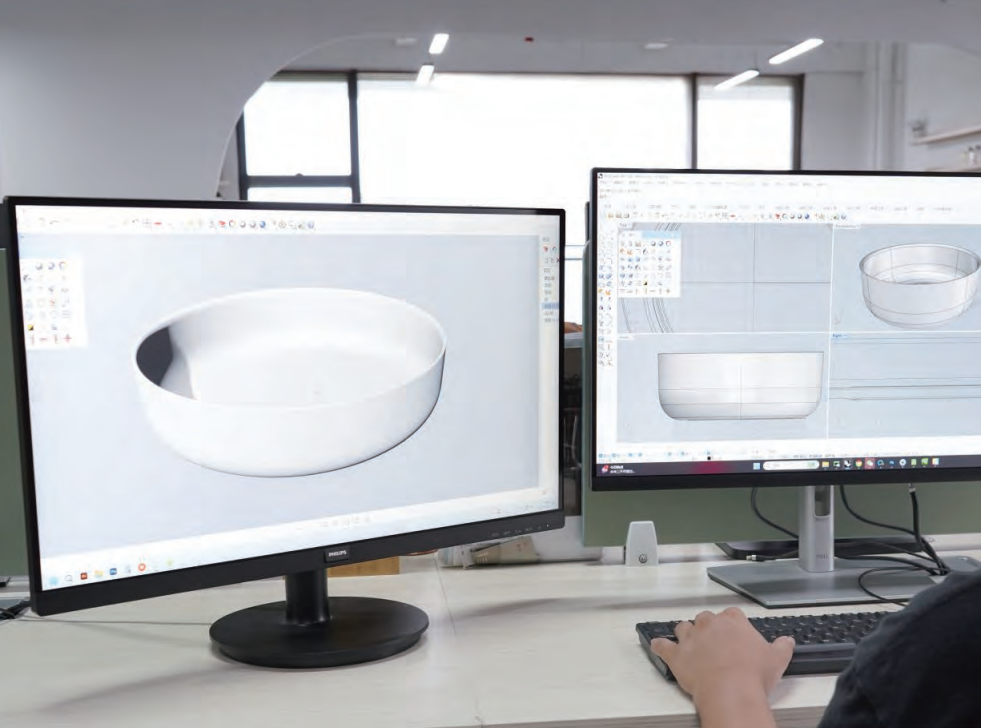

Product design

The exports from our R&D department and high-tech laboratory always give us the best suggestions on materials and offer the latest innovations, and our skilled molding engineers from the production line can give you the correct guidance on what we can realize and what we can’t. Our mold designers study the current trends and your needs,with the advice of our experts and engineers, they are always able to design the products you want.

Create original shapes for you

There are more than 11 passionate product designers working in SHULOPAL R&D centre and factories. SHULOPAL design team studies current usage trends, imaging creative ideas. Their mission is to provide functional, user-friendly, and innovative products.

Our product designers can work with you from the very beginning, to fully understand your needs and ideas, and they will give you the correct guidance on materials, production processes and technologies. Finding the balance between cost, product functionality, and aesthetics.

Get free product design support from SHULOPAL step by step

Step#1 Demand Analysis

The main tasks include:

-Understanding customer needs

-Market competitive product analysis

-Evaluating technical requirements and feasibility

Step#2 Design

The main tasks include:

-Inspiration collection

-Solution discussion

-Solution presentation

Step#3 Program Evaluation

The main tasks include:

-Evaluate the advantages and disadvantages of the solution

-Screen out the best solution

-Evaluate production feasibility

-Propose optimization suggestions

Step#4 Design Optimization

The main tasks include:

-Optimize the design

-Complete the product engineering design

-Complete the renderings and product drawings

Step#5 Design Verification

The main tasks include:

-Sample production

-Design evaluation

Step#6 Output