SHULOPAL is the leading OPAL GLASS manufacturer from China, operates more than 5 OPAL GLASS furnaces, with more than 21 years’ experience in OPAL GLASS manufacturing. Up to now, SHULOPAL produces 0.5 million pieces of OPAL GLASS dinnerware/tableware daily.

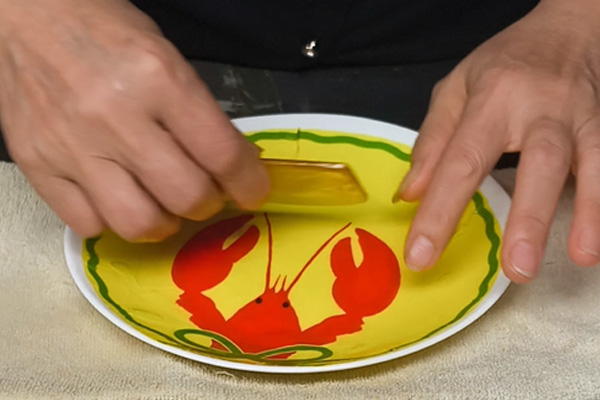

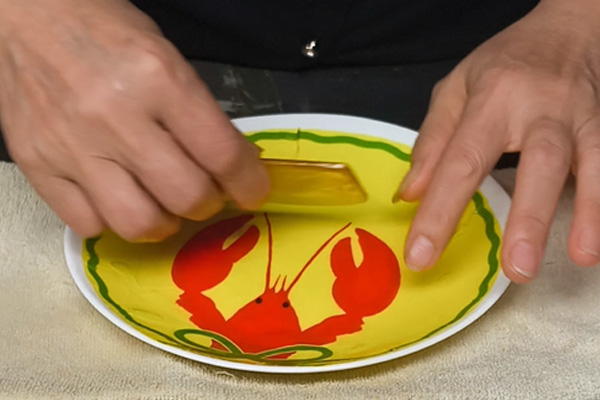

In the production of opal glass, there are two manufacturing processes, pressing and spinning. Opal glass can come in various colors, white, black, gray, green, blue… SHULOPAL continuously improves its production processes and material technologies, ensuring that SHULOPAL OPAL GLASS products remain at the forefront internationally.