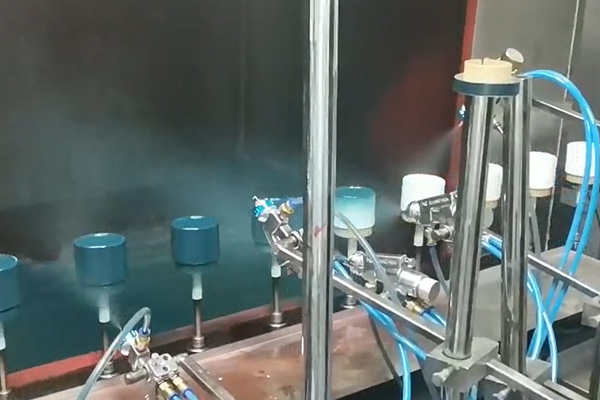

Step#4 Blow Process

The press-and-blow process is the most widely used manufacturing method, In this process, a metal plunger compresses the molten glass into a parison (preform) within a mold. The parison is then transferred to a blow mold and reheated to the optimal blowing temperature before compressed air injection forms it into the final shape.

The blow-and-blow process, conversely, is specialized for narrow-neck glass bottles. Here, compressed air first shapes the parison, which is then 180° rotated and reheated. A second air pressure application inflates the parison against the mold walls to achieve the desired contours.